The rise of digital technologies has been a game-changer across various industries, and inventory management is no exception. With automation and analytics, businesses can optimize their inventory management processes, transition from manual struggles to operational excellence, and maximize profitability. This article will explore how inventory planning software can streamline your operations, the key issues related to inventory management, and how automation can help overcome these challenges.

The Evolution of Inventory Management:

The inventory management landscape has evolved rapidly in recent years, shifting from manual, paper-based processes to digital and automated solutions. This digital transformation has enabled businesses to enhance efficiency, reduce human error, and save valuable time. However, making this transition isn't always straightforward. Organizations often face challenges in implementing new technologies, adapting to changes, and training staff to utilize these systems effectively.

The Key Challenges in Inventory Management:

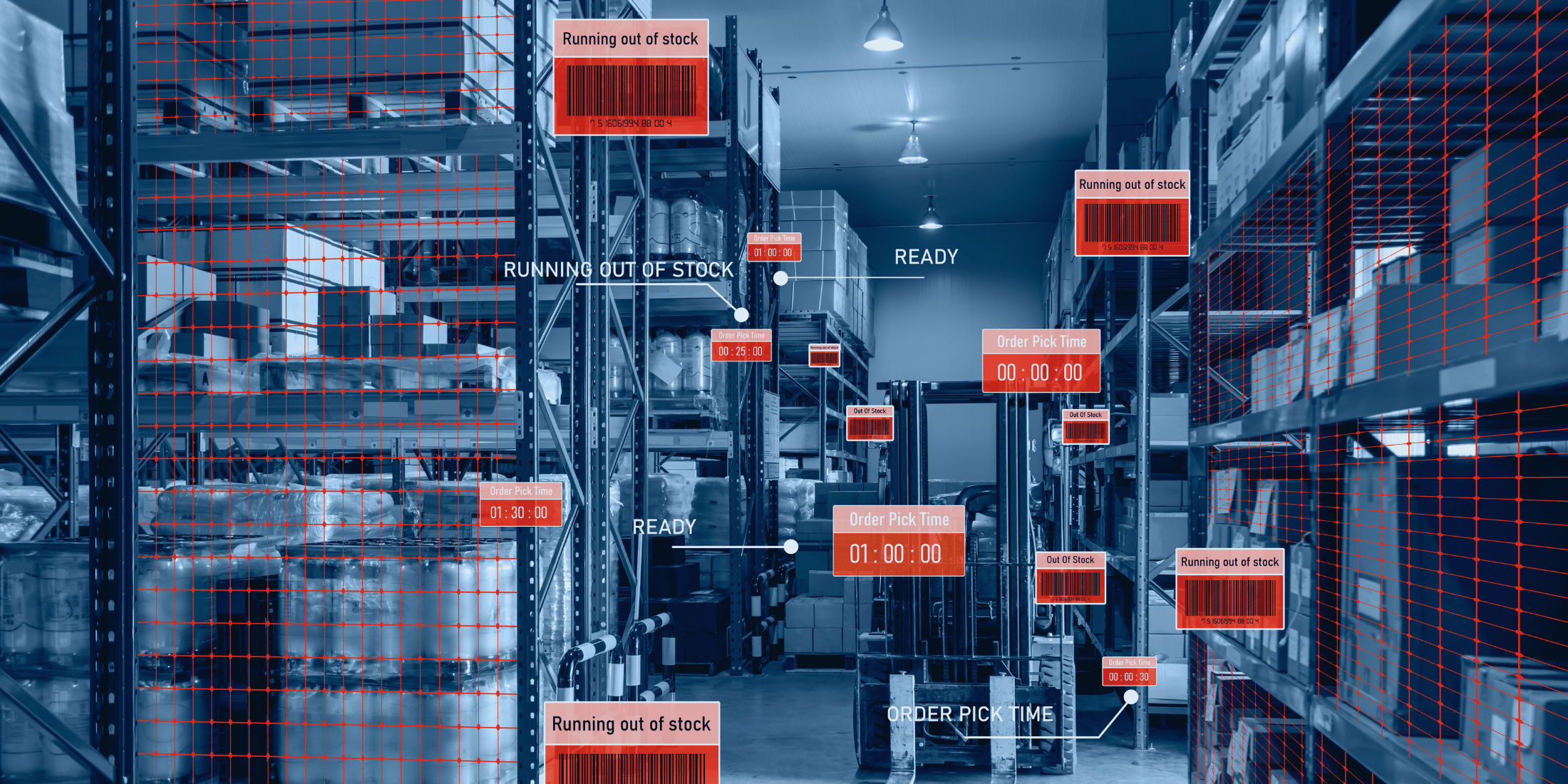

Inventory management is a complex process that involves predicting future demand, sourcing raw materials, maintaining optimal stock levels, and fulfilling orders. Some key challenges businesses face in this realm include overstocking, understocking, inaccurate forecasting, managing supplier relationships, and tracking delivery routes. These challenges can result in lost sales, unsatisfied customers, and increased operational costs.

The Role of Inventory Planning Software in Optimizing Inventory Management

Inventory planning software is a powerful tool that helps businesses tackle these challenges head-on. It uses advanced algorithms and machine learning techniques for accurate demand forecasting, optimizing stock levels, streamlining supplier management, and tracking delivery routes efficiently. The software is a valuable addition to the ERP or CMS, focusing on planning and forecasting rather than replacing the existing inventory management system.

From Manual Struggles to Operational Excellence

Substantial efficiency, accuracy, and speed improvements mark the journey from manual inventory management to digital excellence. Automation eliminates the need for repetitive manual tasks, reducing human error and allowing staff to focus on more strategic activities. Conversely, analytics offers insightful data, helping businesses make informed decisions and predict trends accurately.

Automation and analytics work in synergy to optimize inventory management processes. While automation boosts operational efficiency, analytics provides the intelligence to make smarter decisions.

Benefits of Automation for Inventory Optimization

Implementing inventory planning software offers numerous benefits to businesses. Some of the most prominent ones include:

-

Improved Forecasting: The software uses historical data and predictive analytics to forecast demand accurately, reducing the risk of overstocking and understocking.

-

Efficient Stock Management: It helps maintain optimal stock levels, ensuring that businesses always have enough inventory to meet customer demand without tying up excess capital in surplus or excess inventory.

-

Streamlined Supplier Management: The system aids in managing supplier relationships and tracking delivery routes, ensuring timely deliveries and reducing supply chain disruptions.

-

Enhanced Decision-making: The software enables businesses to make informed decisions and strategies by providing actionable insights and real-time data.

The Integration of Inventory Planning Software

Inventory planning software can seamlessly integrate with your existing CMS or ERP, enhancing their functionality without disrupting your current workflows. This smooth integration allows businesses to implement advanced inventory management techniques without requiring substantial system overhaul or excessive staff retraining.

Facilitated Real-Time Tracking

One of the most significant benefits of inventory planning software is its capability to facilitate real-time inventory tracking across multiple locations. This feature benefits e-commerce and retail businesses operating from different warehouses or stores. It helps maintain an accurate inventory level record, minimizing the risk of overselling or underselling.

Moreover, with an automated system, updates are immediate and reflected in real-time, reducing the possibility of discrepancies due to delayed updates in manual inventory management systems.

Enhancing Supplier Relationship Management

In the context of manufacturing and wholesale businesses, a noteworthy advantage of inventory management automation is supplier relationship management enhancement. Automated inventory management software or systems can monitor supplier performance, keep track of delivery times, and evaluate the quality of supplied goods. This data-driven approach provides a robust foundation for negotiations and can help foster stronger, more productive relationships with suppliers.

Transforming the Supply Chain with Automation

As companies strive to streamline their operations, the supply chain often emerges as a critical area needing improvement. The intricate web of sourcing materials, production, warehousing, and delivery presents many challenges that can significantly impact business operations. Automating this process can mitigate many challenges, transforming the supply chain into a well-oiled machine.

Inventory planning software plays a crucial role in this transformation. It optimises inventory management and provides valuable insights into the supply chain. With real-time data and predictive analytics, businesses can identify bottlenecks, predict potential disruptions, and devise effective strategies to counter them.

The Power of Cloud-Based Inventory Planning Software

In today's hyper-connected world, cloud-based inventory planning software brings many advantages. The cloud offers unlimited storage capacity, scalable solutions, and access to your inventory data anytime, anywhere. It also facilitates team collaboration, enhancing productivity and ensuring all stakeholders are on the same page.

Cloud-based solutions also provide a higher level of data security. Given the sensitive nature of inventory data, safeguarding this information is paramount. Cloud providers typically offer robust security measures, including encryption, access controls, and regular backups, ensuring your data is safe and secure.

Empowering Businesses with Data-Driven Decisions

Perhaps the most transformative aspect of inventory planning software is its ability to empower businesses to make data-driven decisions. Data, such as historical sales data, is the new oil and companies that can effectively utilize this resource have a significant competitive advantage.

By harnessing the power of data analytics, businesses can delve deeper into their operations, gaining a better understanding of customer behavior, market trends, and operational efficiency. They can identify patterns, make accurate predictions, and develop strategies based on solid evidence rather than guesswork.

Ensuring Business Continuity with Automated Inventory Management

A significant advantage of adopting automation in inventory management is its contribution to business continuity. Automated systems ensure your inventory management remains resilient and adaptable when unprecedented events strike. With robust forecasting capabilities and real-time data, businesses can react quickly to changes, whether a sudden surge in demand, supply chain disruptions, or evolving market trends. As such, it allows for effective decision-making regarding inventory replenishment.

In periods of crisis, automated inventory management systems become a key differentiator between businesses that merely survive and those that thrive. By effectively balancing supply and demand, businesses can continue to deliver value to their customers, maintain their market position, and even uncover new growth opportunities.

Streamlining Audit and Compliance

Another area where inventory planning software shines is in audit and compliance. Manual inventory systems can often lead to discrepancies and errors, making the audit process daunting. On the other hand, automated systems maintain accurate, up-to-date records of all inventory movements, making it easier to track items, verify transactions, and ensure regulatory compliance.

Moreover, with automation, businesses can generate comprehensive reports with just a few clicks. This feature not only simplifies the audit process but also provides valuable insights into inventory performance, helping businesses identify areas of improvement and devise effective strategies.

Enhancing Customer Satisfaction

At the heart of inventory management is the aim to meet customer demand efficiently and effectively. Automated inventory management contributes significantly to enhancing customer satisfaction. By ensuring that the right products are available at the right time, businesses can prevent stock-outs, reduce wait times, and meet customer expectations consistently.

Moreover, with accurate forecasting, businesses can better anticipate customer needs and trends, allowing them to stay ahead of the curve and provide a superior customer experience.

The Path to Sustainable Growth

Optimizing inventory management through automation is a stepping stone to sustainable growth. By reducing manual errors, streamlining processes, and providing valuable insights, inventory planning software helps businesses operate more efficiently, make informed decisions, and enhance customer satisfaction—all crucial elements for long-term success.

As we navigate the evolving landscape of inventory management, businesses must remain adaptable, ready to embrace new technologies, and open to changing traditional ways of working. Only then can they truly leverage the power of automation and analytics to transition from manual struggles to operational excellence.