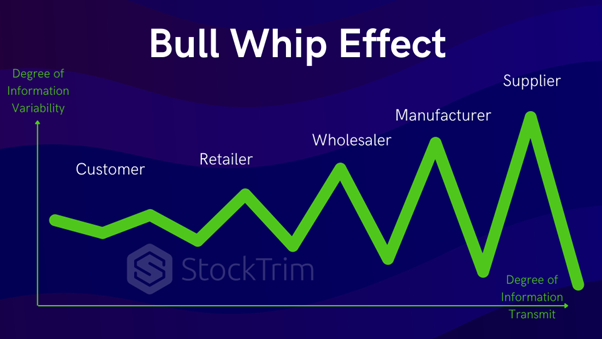

The bullwhip effect is a phenomenon that can happen in inventory management. It happens when there is too much inventory in the supply chain and it moves in a whip-like pattern.

The concept first appeared in Jay Forrester's Industrial Dynamics (1961) and thus it is also known as the Forrester effect.

It has been described as “the observed propensity for material orders to be more variable than demand signals and for this variability to increase the further upstream a company is in a supply chain”

When you look at this from above, it looks like the shape of a bullwhip. The bullwhip effect can be extremely harmful for your business because it has a negative impact on cash flow, makes your company spend more on storage, and lead to stock-outs.

In this article we’ll explain in layman's terms what the bull whip effect is and how inventory planning software can help you avoid it.

What is the Bull Whip Effect?

A bullwhip effect happens when inventory is too high in the supply chain. This is also known as “inventory build”. The inventory keeps moving through the supply chain, “whipping” back and forth. Because there’s too much inventory, it takes a long time to move through the supply chain. And if there’s a disruption, it has a big impact because there is so much inventory. The bull whip effect is one example of a “flow problem” in supply chain management. It happens because there’s too much inventory in the supply chain and it takes too long to get through.

Inventory Planning to Avoid the Bull Whip Effect

Inventory planning is one of the most important aspects of inventory management. It’s one of the best ways to avoid the bull whip effect. It’s about creating an accurate forecast for how much inventory you need, when you need it, and where it needs to be delivered. For example, if a product is selling well at your store, you might realize you need more inventory. How does inventory planning help you avoid the bull whip effect? It helps you understand when you need to have new inventory delivered and where it needs to go. It also helps you understand when you need to remove inventory from the supply chain.

We spoke to Paul Simpson, Co-Founder from Inventory Planning SaaS StockTrim, who outlines important things to consider when mitigating the Bull Whip Effect,

1. Base your actions from actual customer demand

The orders you place with your supplier, or your manufacturing team should be based on the forecasts of what you’re expecting your customers to buy in the future “lead time days” from now. Not from previous production jobs or previous supplier purchase orders.

If your orders are based on previous actions then any mistakes you made would be amplified and repeated. StockTrim always bases its forecasts from actual customer demand – the sales orders your customers have made – then compares that with stock on hand, stock on order, and your expected stock at the time, to calculate your optimal order quantities to place now so that your inventory is as accurate as possible when you need it.

2. Have suitable safety stock / buffer stock

It’s important to consider the acceptable stock risk when deciding how much to carry, which is denoted by your service level – the probability of not going out of stock. Crucial items may need a service level of above 95%, whereas others may have an acceptable level of 80% or less. When a system like StockTrim calculates your optimal buffer stock, it takes this service level and the variability of demand into account so that items with more sporadic demand will be higher, since they are less predictable and you’ll need to have stock on hand to cover occasional spikes.

If you have noticed that your customer demand has recently become more irregular, your buffer stock may increase as a result. If you wish to avoid a bloated inventory you may wish to lower your service levels for less crucial items so that the amount of buffer stock you carry will not explode to higher levels than needed.

3. Smooth out orders to ignore short term erratic demand, and focus on the overall trend

In a changing environment, your demand may become more irregular and less predictable. It’s often tempting to make a ‘knee jerk’ reaction if you are accidentally cut short on occasion and order more stock in the future to cover the same scenario, even though it may not be a common occurrence going forward. Similarly, if you notice you have a bloated inventory of historically low moving specific items and your sales team make a temporary effort to move this inventory on, this could be accidentally interpreted as a spike in demand causing you to order or manufacture even more of these generally low moving items, so not solving the original problem. A good forecasting system should have checks in place, or algorithms, to ensure that temporary irregularities in demand are not carried forward, but on the other hand genuine changes in demand are accounted for in the future. It can be complex and difficult to tell this difference – what we do with StockTrim is to use a machine learning method which is able to correlate trends in products with wider amounts of data to be able to detect this with reasonable accuracy and then calculate your future customer demand forecasts based on that.

4. Keep an active eye on forecasts yourself if demand is rapidly changing

Even though software tools are an essential part of managing your inventory and forecasts, especially when there are large datasets, they are only as accurate as the data they can access. So if you know that future demand is going to be different than recent trends then it’s important that you input this into the system. In StockTrim you can set your own forecasts explicitly, which will then be taken into account in your supplier order calculations, especially the components to order for manufactured items. You can also set the overall trend as a percentage – for example if this years demand is 20% less because last years was artificially high due to the pandemic, you can set a negative growth figure so that the forecasts will be lower and you can avoid a bloated inventory.

In summary, the bullwhip effect indicates that errors in assessing consumer demand has been amplified through a supply chain. Better communication among supply chain partners, better forecasting methods, and a highly demand-driven approach can help reduce inventory waste, customer service issues, and over-stocking that result from the bullwhip effect.