For 15 years Angel Food has been striving to make plant-based foods more accessible to Kiwis wanting an alternative to dairy. In 2014 the company launched its very own dairy-free mozzarella, the first commercial vegan cheese to be made in Aotearoa.

The Auckland, New Zealand company’s range of plant-based and allergy-friendly products now include several cheese varieties such as, cream cheese, cheddar & parmesan. Sold into supermarkets and food wholesalers throughout Aotearoa, and used by hundreds of eateries and quick service restaurants including Hell Pizza, Lord of the Fries, and Zambrero.

Justin Maher joined Angel Food early in 2021 as Production Coordinator and Food Technologist. As part of a lean and flexible team, he was given responsibility not only for new product development and quality assurance, but also for scheduling and production.

Justin Maher joined Angel Food early in 2021 as Production Coordinator and Food Technologist. As part of a lean and flexible team, he was given responsibility not only for new product development and quality assurance, but also for scheduling and production.

This meant ensuring the company’s contract manufacturer received the right raw materials in time for every production run.

“It was daunting for me to jump into this without supporting software,” Justin says.

“Every product has a list of components and some have a lead time of 70-90 days, so you really don’t want to forget about ordering materials.”

The challenge was to ensure there was enough product, but not too much.

“If you run out of stock you not only lose revenue, but also reputation and trust. If you order too much, you risk having it expire, selling cheap or dumping. You also create a cashflow issue if you’re over-ordering.”

Maintaining inventory is made more complex by the fact that Angel Food contracts production to a Tauranga-based manufacturer. While communication is regular and accurate, there is nothing like having the physical stock in front of you.

When Justin first joined Angel Food, Inventory control & forecasting was managed only via spread-sheeting data from their general stock, orders and sales platform Cin7. With a background in Food Technology rather than inventory control, Justin was uneasy about relying on simplistic spreadsheets only.

“We were basing our forecasts off excel spreadsheets and sales for the last two months, which obviously gives you limited information.”

The options were to employ another person with more inventory planning experience, or find an inventory forecasting tool that could integrate with Cin7 and automate that part of the process. StockTrim filled the bill as it’s supported by Cin7, offers good value for money and “covers the basics really well”.

Never Run Out Of Stock

Integrating Stocktrim’s software required some specific coding to account for a few quirks in Angel Food’s inventory system, and Justin says StockTrim’s team took care of this without fuss. Within a month Angel Food had “integrated everything to where we were really confident with the numbers”.

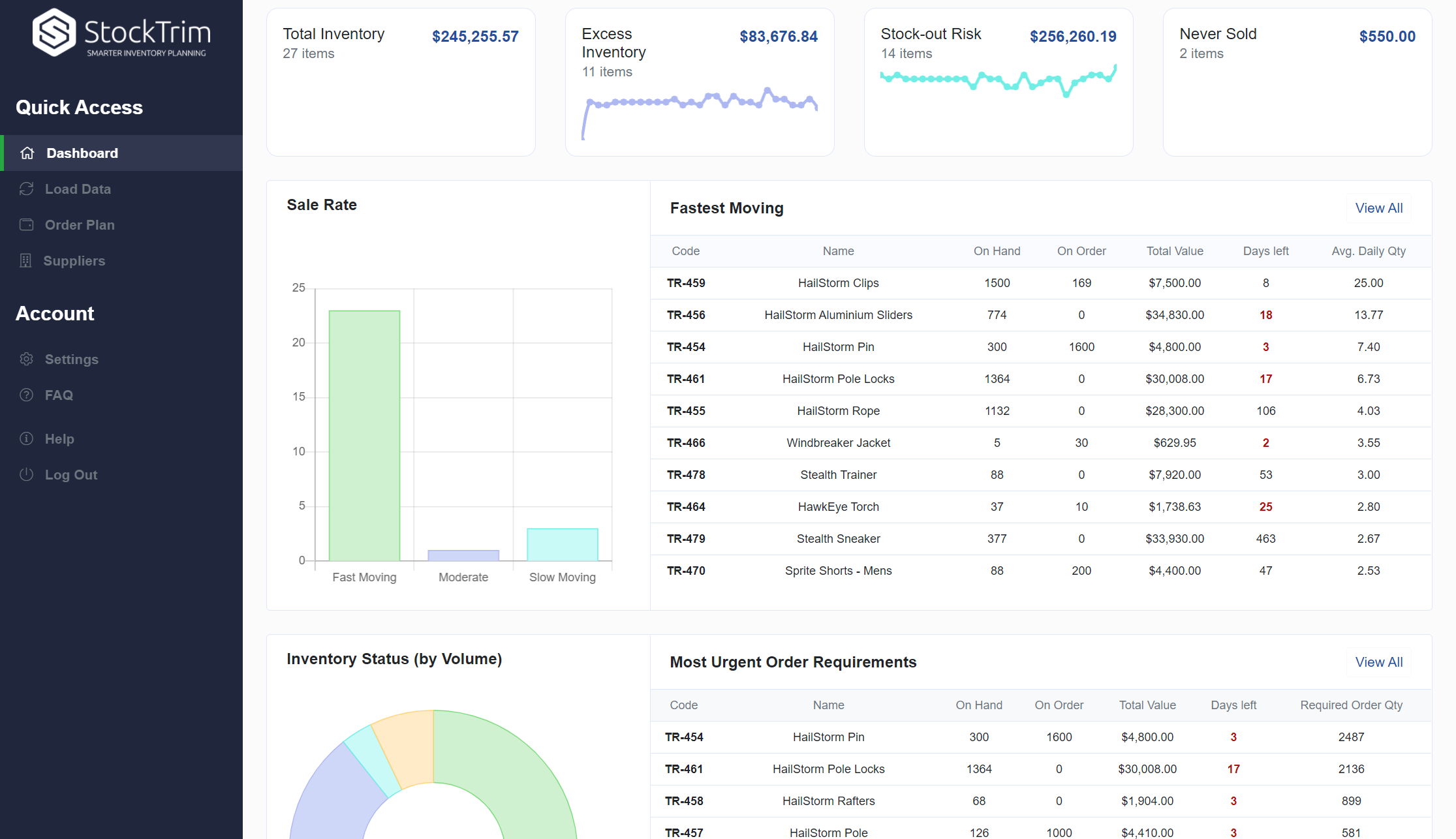

“Stocktrim makes it very clear on your home page how much stock you have, and encourages you to keep it as lean as possible.”

As well as giving Angel Food security of supply, StockTrim has provided the opportunity to analyse seasonal sales fluctuations. With StockTrim, you can click on any product and see how its sales have changed month to month.

“It’s a very quick method to look at our historic sales and all that information helps us with making longer term decisions.”

This includes tracking sales of marginal products to decide whether to keep them in the range, and driving focus into higher growth products.

Impact of Covid-19

Covid-19 has made seasonal trends less reliable but with the latest lockdown, Justin could quickly review and quantify previous lockdown sales information. This is crucial to make quick and confident decisions which best serve a variable customer base.

StockTrim makes it easy to add extra lead time, and Justin used this to Angel Food’s advantage.

“When you walk around the supermarket you can see that some suppliers weren’t prepared and their products ran out. Because the food service had dropped off, we really had to make sure we made the most of that extra demand from retail.”

Having decided to err on the side of caution with lead times due to international shipping fluctuations, Justin receives alerts of things going out of stock well in advance. Suppliers are often contacted well before the factory even knows they’re running out of stock.

This decision proved its wisdom recently when stock was ordered well before the factory requested it, there was a huge shipment delay, but despite this, the order arrived just day later than required. Production was able to be informed well in advance to reschedule and maintain finished stock levels. Without StockTrim, production could have easily ceased for many weeks.

“It would have been a lot worse if the supply was even a week late,” Justin says.

StockTrim is easy to use and has provided enough inventory security that Justin has been able to train a colleague to take on the ordering of raw materials, leaving him to focus on the bigger picture of scheduling finished goods.

“I don’t think I would have had the confidence to do that, and my colleague wouldn’t have been confident to take it on, without StockTrim.”

Would you like more confidence in managing your inventory?

Join the growing global community of businesses using StockTrim.

Trial StockTrim today for 14 days FREE, with no credit card required.